Business Challenges

- Design and manufacture a compact tokamak

- Deliver an engineering solution to demonstrate breakthrough physics

- Demonstrate energy gain from fusion

Keys to Success

- Use industry-leading design tools of Solid Edge

- Accelerate decision making

- Use Solid Edge simulation to confirm structural performance

Results

- Re-use of design data cuts development time

- Precise geometry ensures designs are right first time

- Rapid decision making – down from days to minutes

Case study Tokamak Energy

Tokamak Energy is a private company with an innovative approach: to produce fusion energy within a compact device only a few meters wide. David Kingham, chief executive officer, explains: “Our aim is to be the first to commercialize fusion and the first to create a fusion device that produces an energy gain. We designed the world’s first high-field spherical tokamak to take full advantage of this class of device.”

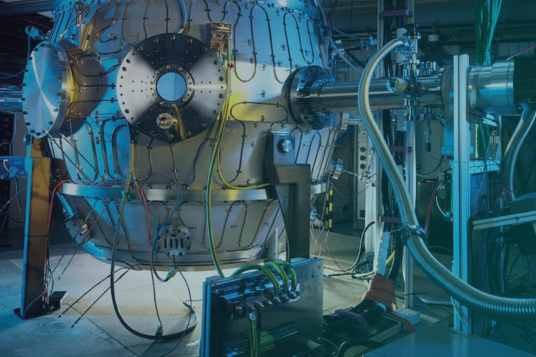

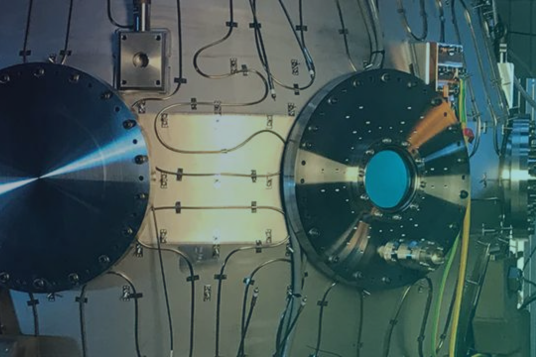

Tokamak Energy has produced two laboratory prototypes, achieving a world first with the ST25 HTS, which demonstrated the use of high temperature superconductor (HTS) magnets. “Our latest design, ST40, uses copper magnets but is much more of an engineering challenge as we are aiming for exceptionally strong magnetic fields, up to three Tesla at the centre of the plasma.”

Business Challenges

The ST40 device weighs 50 tons and is constructed using easy-to-machine special steel and copper alloys known for their corrosion resistance, heat resistance, low magnetic permeability, high conductivity, and structural stability. Tokamak Energy employed Solid Edge® software, implemented in 2014 with the help of Siemens Digital Industries Software partner OnePLM, for its design. The company is also adopting Teamcenter® software for product development management.

Bill Huang, senior tokamak engineer, states, "We chose Solid Edge because it offers industry-standard tools with excellent parametric capabilities to address our design challenges."

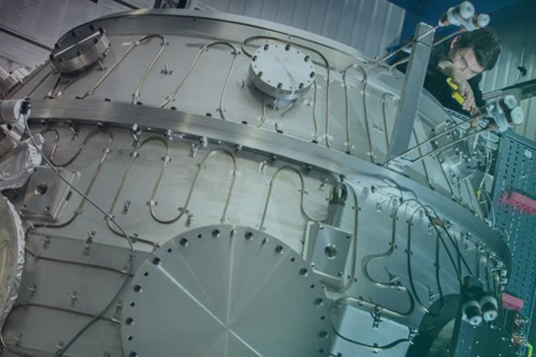

Paul Tigwell, mechanical design consultant at Tokamak Energy, elaborates on the complexity of the project, including the 24 rods in the center column's helical shape and the intricate assembly of toroidal field coil outer limbs. He praises Solid Edge for its precision, intuitiveness, and ease of learning for new users.

Keys to Success

"We began with a clean slate, crafting everything in a virtual environment," Lockley states. "Solid Edge facilitates multi-level communication, allowing us to share geometry for designing new components. Its visualisation capabilities greatly enhance communication, especially with colleagues and partners beyond our design office. What used to take days for decision-making can now be accomplished within minutes."

Huang emphasizes the effectiveness of Solid Edge, particularly in collaborative settings, saying, "Solid Edge is outstanding, especially when multiple team members are simultaneously working on different development aspects. It truly fosters collaboration."

For Tokamak Energy, Solid Edge transcends mere design; it plays a vital role in problem detection and equipment identification. Tigwell explains, "Solid Edge helps us foresee issues and determine the precise manufacturing and assembly process before implementation. For instance, we realized that certain removable components in ST40 were beyond the crane's reach, necessitating a bottom-to-top assembly approach."

Design team members share drawings and STEP files with suppliers and print hard copies directly from Solid Edge for workshop colleagues to review manufacturing and assembly procedures. Future workshop plans involve providing access to 3D PDF files from Solid Edge, allowing technical operators to rotate models and zoom in for specific details.

Results

“We believe that now is a great time to be involved in fusion as an innovative and fast-moving business,” Kingham comments.

“As we are investor-driven, the big question is always how quickly we can build and improve our prototypes. With Solid Edge, we can do very quick updates between different configurations and that gives us huge agility.”

“We are tackling one of the very biggest challenges that mankind faces - To do this we have to be using the best-in-class materials and technologies, including the best design tools for the job – and that is where Solid Edge comes in.”