Get a 30-day Free Trial

Try Simcenter Femap tools today!

REQUEST A FREE PRODUCT GUIDE

Get Product Guide

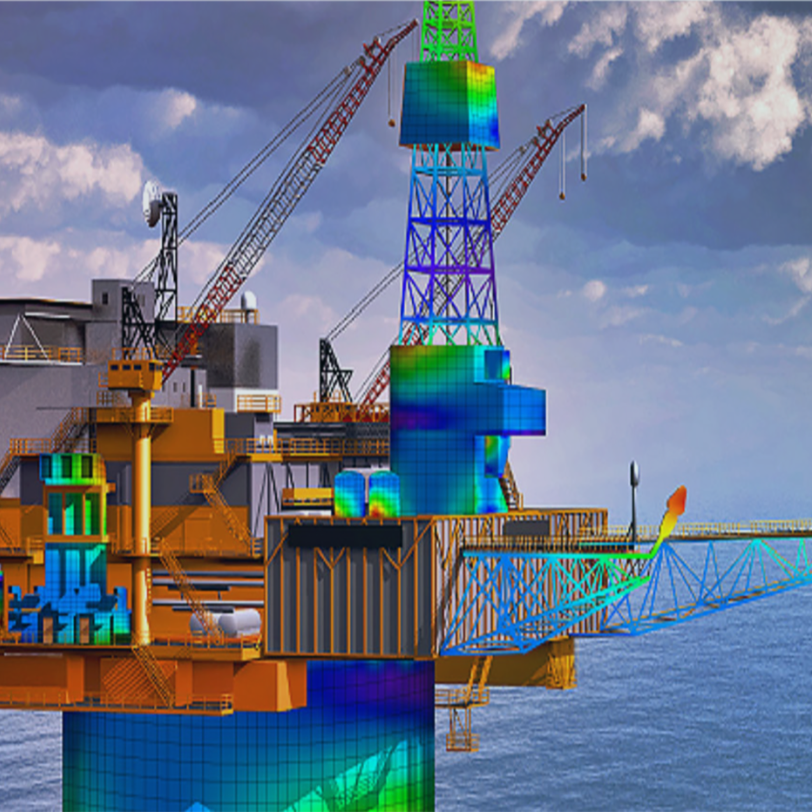

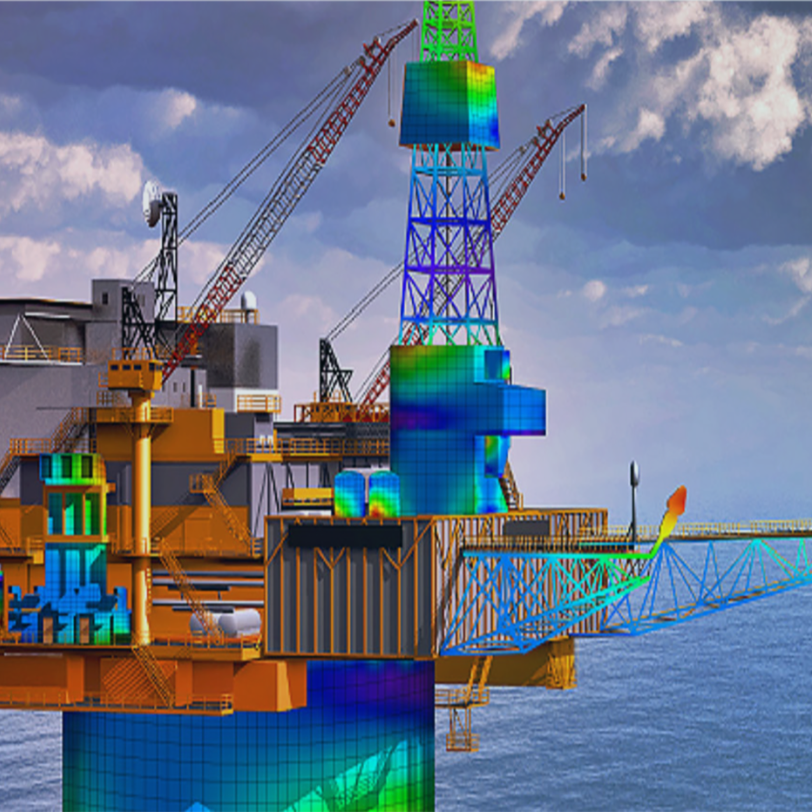

Simcenter Femap software is a standalone finite element modeling (FEM) pre- and postprocessor for engineering simulation and analysis.

The software is computer-aided design (CAD) independent and can import geometry from all major CAD platforms and supports most CAD data formats. Enquire now about this software.

Learn more about Simcenter Femap by exploring our downloads. Simcenter Femap software is a standalone finite element modeling (FEM) pre- and postprocessor for engineering simulation and analysis. Start your Simcenter Femap journey today.

Simcenter Femap, a powerful FEA tool, empowers engineers with advanced simulation for analysis and optimization of complex engineering systems.

Effortlessly transition from CAD to analysis model. Unique CAE tools for rapid meshing, assembly management, and results analysis

Simcenter provides the Structural Analysis software you need to simulate a wide range of applications, all within a single user environment.

Best-in-class Simulation capabilities that help you understand your product and tailor your management solution for optimal performance.

CFD method allows engineers to predict complex fluid dynamics problems virtually and turn these insights into product innovation.

Simcenter Femap Composites provides advanced simulation tools for in-depth analysis and optimization of composite materials and structures.

| NX MACH Designer |

NX Layout |

NX MACH 1 Design |

NX MACH 2 Product Design |

NX Cool Shape Design |

NX MACH 3 Product Design |

NX MACH 3 Industrial Design |

|

|---|---|---|---|---|---|---|---|

| Feature category | |||||||

| Feature | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Feature | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Feature | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Feature | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Feature | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Feature | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

Try Simcenter Femap tools today!

The software is Computer-Aided Design (CAD) independent and can import geometry from all major CAD platforms and supports most CAD data formats. Simcenter Femap also works in combination with a wide variety of FEA solvers, including Simcenter Nastran software.

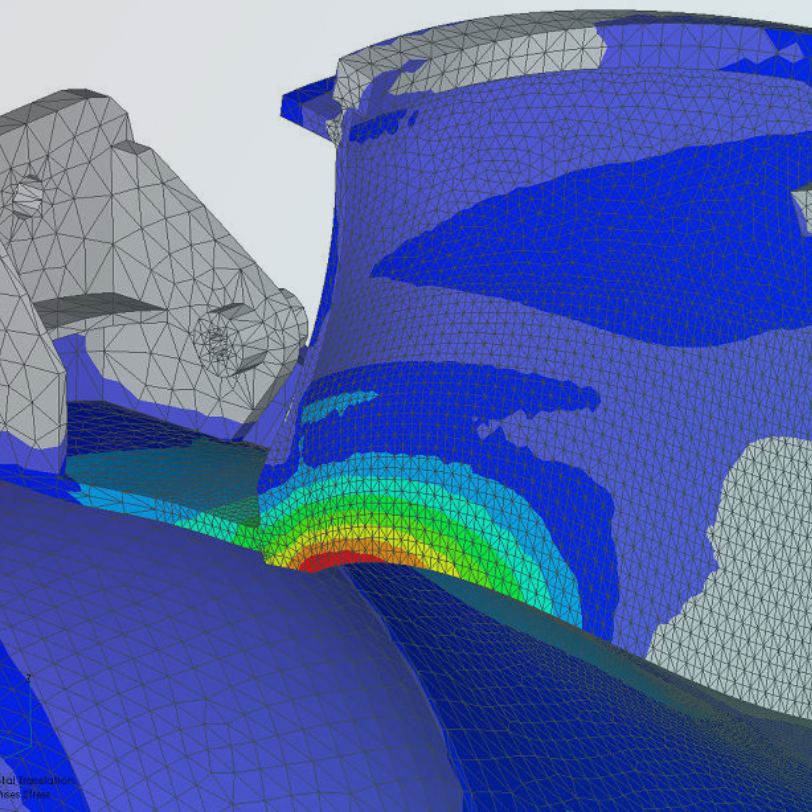

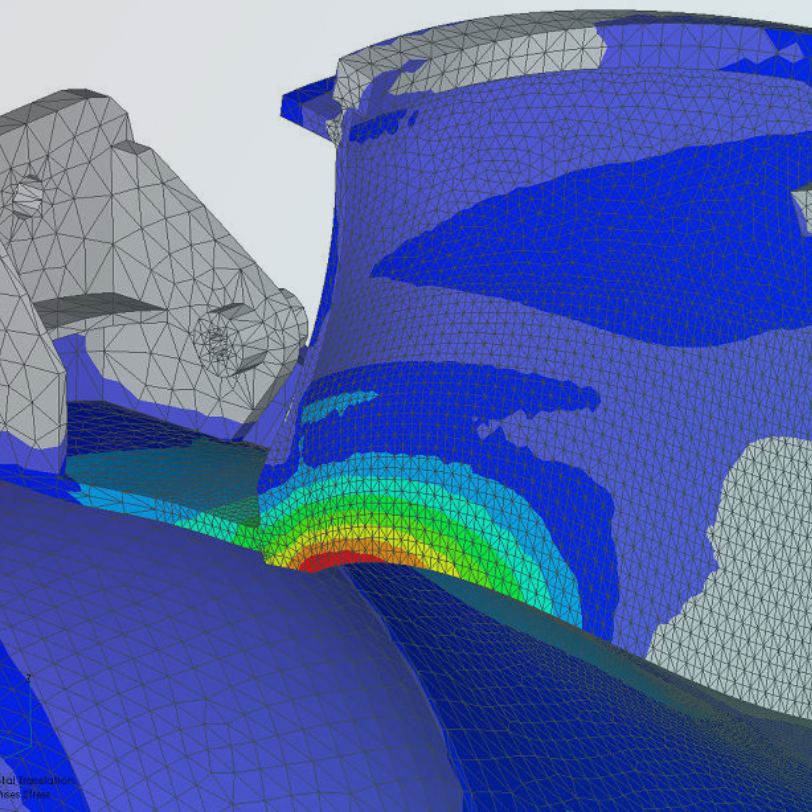

Improve the quality of your hex mesh by utilising a suite of refined tools. Notable improvements in the meshing toolbox's sizing and surface functionalities now enable seamless updates to a hex mesh.

Gone are the days of tediously selecting multiple curves; these advancements ensure the precise propagation of the mesh across all necessary solids with finesse and ease.

Try Simcenter Femap tools today!

The software is Computer-Aided Design (CAD) independent and can import geometry from all major CAD platforms and supports most CAD data formats. Simcenter Femap also works in combination with a wide variety of FEA solvers, including Simcenter Nastran software.

Improve the quality of your hex mesh by utilising a suite of refined tools. Notable improvements in the meshing toolbox's sizing and surface functionalities now enable seamless updates to a hex mesh.

Gone are the days of tediously selecting multiple curves; these advancements ensure the precise propagation of the mesh across all necessary solids with finesse and ease.

In the competitive landscape of industrial machinery, the relentless pursuit of innovation is the hallmark of success. For XYZ Corp, a longstanding player in the industry, this pursuit was no less than a mission.

Faced with the challenge of keeping pace with the rapid advancements in technology, they embarked on a transformational journey that would redefine the way they approached manufacturing.

In the competitive landscape of industrial machinery, the relentless pursuit of innovation is the hallmark of success. For XYZ Corp, a longstanding player in the industry, this pursuit was no less than a mission.

Faced with the challenge of keeping pace with the rapid advancements in technology, they embarked on a transformational journey that would redefine the way they approached manufacturing.

In the competitive landscape of industrial machinery, the relentless pursuit of innovation is the hallmark of success. For XYZ Corp, a longstanding player in the industry, this pursuit was no less than a mission.

Faced with the challenge of keeping pace with the rapid advancements in technology, they embarked on a transformational journey that would redefine the way they approached manufacturing.

Simcenter Femap is a powerful finite element modelling and simulation software that enables engineers to create and analyse complex engineering systems for various industries.

Simcenter Femap allows engineers to accurately model and simulate structural, dynamic, and thermal performance. It offers efficient meshing, visualisation, and is a trusted solution used across industries for decades.

Yes, Simcenter Femap is user-friendly and designed to cater to both novice and experienced engineers. It offers an intuitive interface and extensive training resources.

Yes, Simcenter Femap provides collaboration tools that facilitate working with colleagues, suppliers, partners, and customers, enhancing communication and productivity.

Simcenter Femap allows for structural, dynamic, and thermal simulations, enabling engineers to evaluate how components and systems respond to real-world conditions.