Get a 30-day Simcenter 3D trial

Try Simcenter 3D tools today.

REQUEST A FREE PRODUCT GUIDE

Get Product Guide

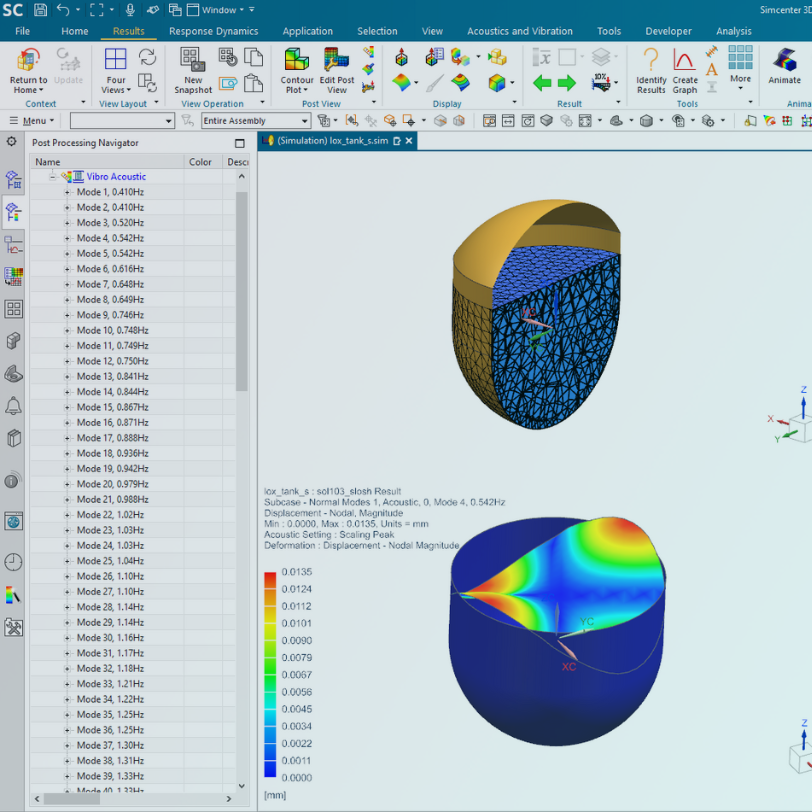

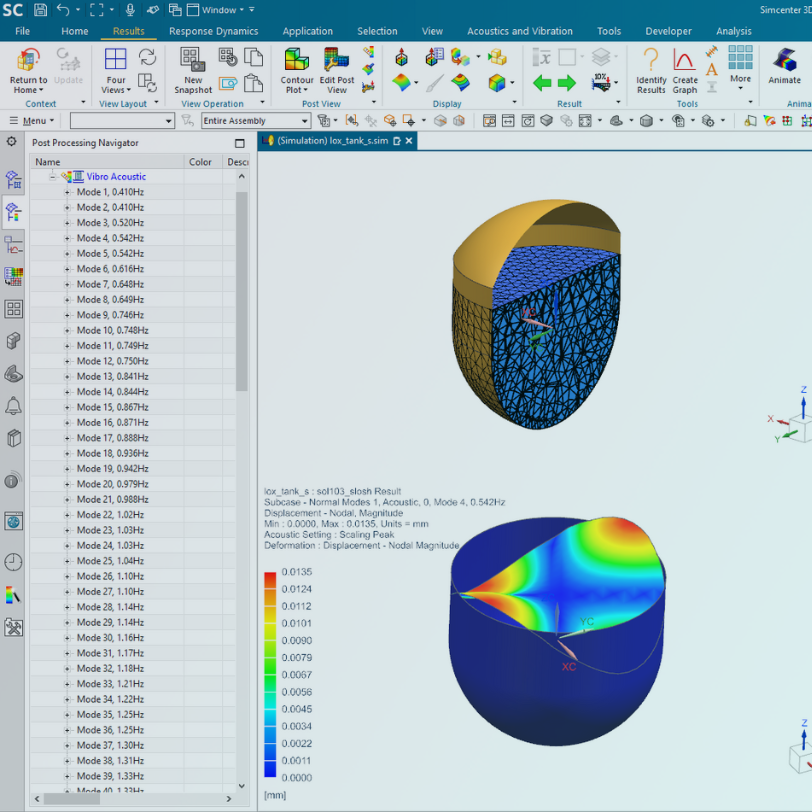

Siemens Simcenter 3D software is an advanced and powerful CAE environment. Used by thousands of engineers globally for some of the most challenging product testing, Simcenter is a broad set of advanced tools that can be tuned to fit your product exactly as needed.

Simulation and analysis can be carried out quickly and easily with extensive geometry editing capabilities, associative simulation modeling and multi-discipline solutions. Enquire now about this software.

Explore our downloads to learn more about Simcenter 3D and how it can help you address complex engineering challenges by enhancing simulation efficiency. As one of the most comprehensive, fully-integrated CAE solutions available, Simcenter 3D is your gateway to advanced engineering capabilities.

Simcenter 3D is integrated seamlessly with NX CAD allowing for rapid creation of simulation models and associative design iterations.

The powerfull meshing algorithms within Simcenter 3D allow for fast and accurate meshing of even the most complex geometries.

Simcenter 3D offers an entire array of solutions spanning multiple physics from a centralized platform.

Simcenter 3D has a powerful range of own solvers but also supports the other commonly used FEA solvers in the market like Ansys, Abaqus or LS-Dyna.

Simcenter 3D offers a connection to Teamcenter PLM for managing the simulation data and keeping track of changes.

| NX MACH Designer |

NX Layout |

NX MACH 1 Design |

NX MACH 2 Product Design |

NX Cool Shape Design |

NX MACH 3 Product Design |

NX MACH 3 Industrial Design |

|

|---|---|---|---|---|---|---|---|

| Feature category | |||||||

| Feature | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Feature | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Feature | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Feature | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Feature | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Feature | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

Try Simcenter 3D tools today.

Siemens Simcenter 3D software is an advanced and powerful CAE environment. Quick and easy simulation and analysis are achievable with its extensive geometry editing capabilities, associative simulation modelling, and multi-discipline solutions.

Emixa supports you every step of the way, with decades of experience and a talented team to help transform your business.

Simcenter 3D offers efficient laminar composite modelling using zone-based and ply-based techniques. It maintains model associativity with the geometric design and collaborates seamlessly with Fibersim composites engineering software.

Try Simcenter 3D tools today.

Siemens Simcenter 3D software is an advanced and powerful CAE environment. Quick and easy simulation and analysis are achievable with its extensive geometry editing capabilities, associative simulation modelling, and multi-discipline solutions.

Emixa supports you every step of the way, with decades of experience and a talented team to help transform your business.

Simcenter 3D offers efficient laminar composite modelling using zone-based and ply-based techniques. It maintains model associativity with the geometric design and collaborates seamlessly with Fibersim composites engineering software.

Discover the transformational power of our PLM solutions through our compelling partnership with ART Group. Explore this case study to witness how our expertise and innovative technology have propelled ART Group to new heights in product development and lifecycle management, revolutionizing their operations and achieving remarkable results.

%2015%25.png)

Discover how Brabant Engineering, in collaboration with Siemens Simcenter 3D, revolutionized the design and development of marine stabilizers for DMS Holland. By leveraging Simcenter's comprehensive simulation capabilities, Brabant Engineering achieved unparalleled precision in analyzing and optimizing their Magnus Master rotor stabilizer technology. The implementation of Siemens Simcenter streamlined their design processes, reducing prototyping cycles, cutting development costs, and establishing DMS Holland as a frontrunner in boat stabilizer solutions.

%2015%25-19.png)

Simcenter 3D enhances efficiency with its advanced analysis and optimisation tools, streamlining product development through early identification and resolution of design issues.

Simcenter 3D can help solve complex problems, whether it's optimising product designs, ensuring durability, enhancing energy efficiency, or simulating real-world operating conditions.

User Simcenter 3D offers powerful capabilities for multi-disciplinary simulations, design exploration, and optimisation, allowing engineers to make informed decisions, reduce development time, and enhance product performance.

Yes, Simcenter 3D is designed for a wide range of users, from beginners to experts, providing user-friendly tools and extensive training resources.

Simcenter 3D includes features that promote teamwork, enabling engineers to collaborate effectively, streamline workflows, and share results with colleagues and stakeholders.