- Home

- Product Lifecycle Management

- Simulation

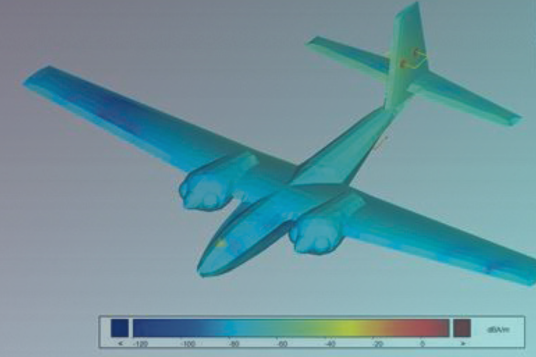

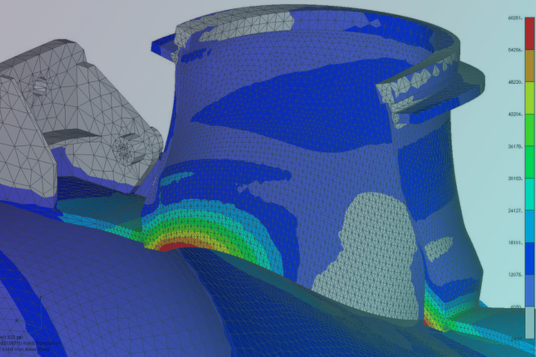

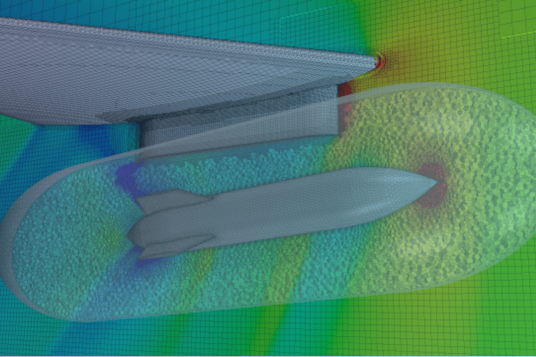

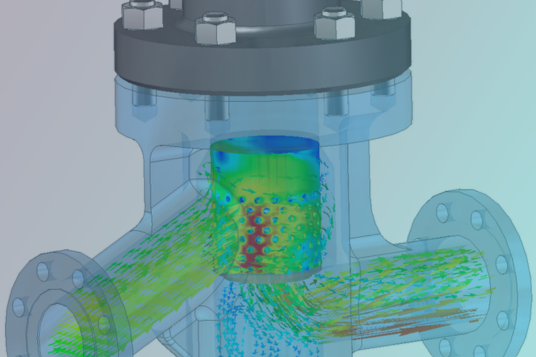

Simulation Software

Simcenter 3D Software

Simcenter Femap Software

Simcenter STAR-CCM+ Software

Simcenter FLOEFD Software

Simcenter Amesim Software

%2035%25.jpg)

Moldex3D Software

Driving Innovation: How Emixa Powers Our Progress

"Emixa understands our software needs thoroughly and assists us impeccably with our simulation requirements. Whenever we encounter specific queries, reaching out to Emixa is our go-to solution. Without this open line of communication, our product development would face disruptions. Hence, maintaining a constant dialogue is pivotal for us."

Elevate your Industry with Emixa: our Unique Advantages

Virtual Prototyping

CAE software enables realistic simulations, reducing the need for physical prototypes, saving time and resources.

Multiphysics Analysis

Provides a holistic view by simulating multiple physical phenomena concurrently, ensuring comprehensive product evaluation.

Early Issue Detection

Identifies design flaws and weaknesses in the early stages, allowing for timely adjustments and cost-effective improvements.

Optimisation

Facilitates iterative design processes, optimising product performance and efficiency through continuous refinement.

Cost Reduction

Minimises the need for extensive physical testing, leading to significant cost savings in terms of materials and testing facilities.

Fast Decision-Making

Provides valuable insights into design performance, supporting engineers and designers in making informed decisions for better product outcomes.

“We had to make something as light as a car engine, but as strong and robust as a big truck engine”

We Have Extensive Simulation Experience

With a wide range of CAE experience, we offer leading simulation solutions that enable optimised designs. Benefit from cost-effective solutions and accelerated product development.

VIEW ALL CASES

%2015%25-13.png)