Get in Touch for More Insights

Excellence and efficiency in industrial machinery & heavy equipment.

Trend #1

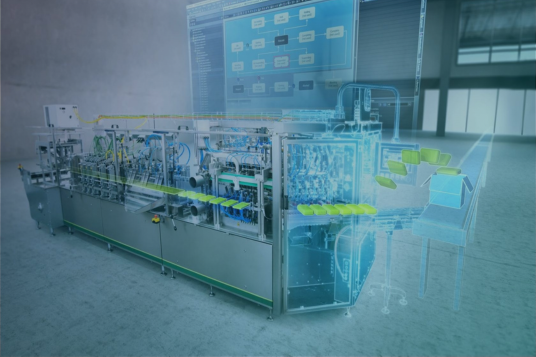

Increasing adoption of Industry 4.0

Trend #2

Sustainable and environmentally friendly

Trend #3

Digital tools and technologies in supply chain

Trend #4

Personalised and customised products

Explore a wide range of industrial machinery and heavy equipment success stories from our portfolio. View all cases to see how our solutions drive innovation in this sector.

VIEW ALL CASES

.png)

At Emixa, we have decades of experience serving the Automotive and Transportation industry. From SMB's to large OEM's, we serve a range of businesses.

Excellence and efficiency in industrial machinery & heavy equipment.

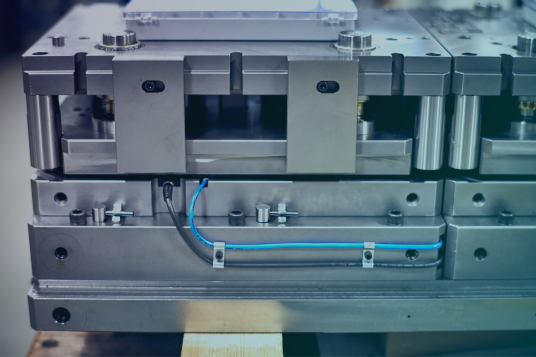

Learn how our collaboration with NTS transformed the landscape of industrial machinery and heavy equipment. Our comprehensive approach integrates cutting-edge technology, precision engineering, and advanced software solutions to optimise performance, reduce operational costs, and enhance sustainability. Dive into the details of our partnership with NTS and discover how our team of experts, with years of experience in utilising Siemens' Teamcenter software, continues to drive innovation and elevate product lifecycle management in this dynamic industry.

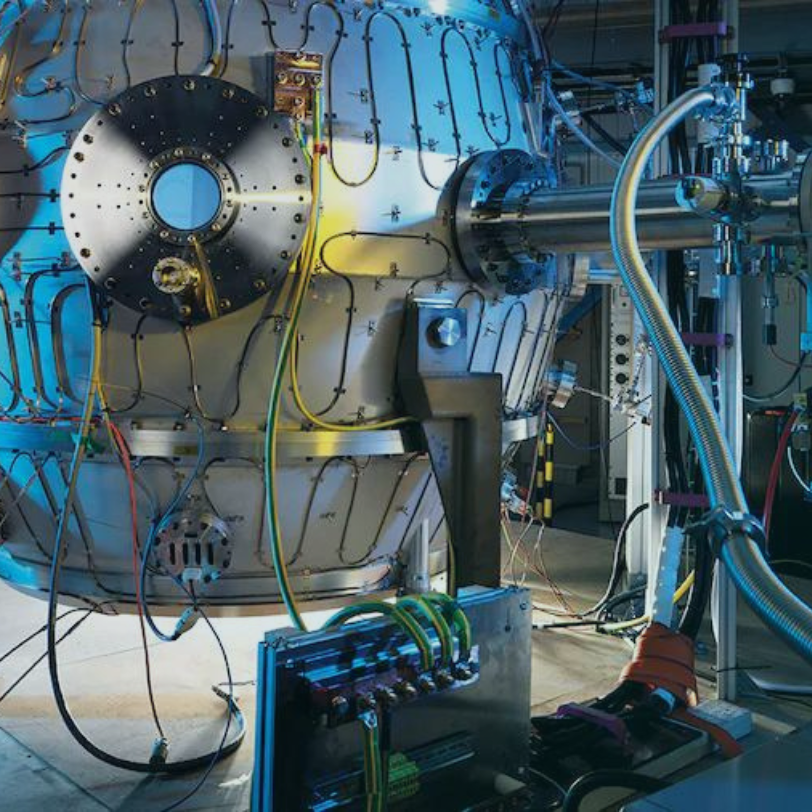

AESSEAL, a company specializing in preventing leaks of liquids and gases, implemented Teamcenter to streamline workflows, reduce manual processes by 75%, and improve data reliability. Teamcenter now automates part number generation, stock records, and bills of materials, while also integrating CRM data for enhanced decision-making.

This platform supports global expansion and safeguards intellectual property. With the support from Emixa, AESSEAL has embraced a global engineering approach, enabling them to focus on worldwide expansion while ensuring continued customer service excellence and business growth.

.png?width=1668&height=1251&name=Ontwerp%20zonder%20titel%20(2).png)

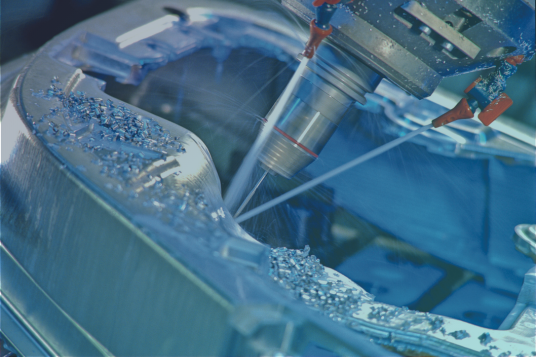

New Wave Engineering, a dynamic machine factory serving diverse industries, faced the challenge of upgrading from I-DEAS software while maintaining compatibility with a crucial client. They sought a versatile solution to meet automotive and broader industry needs. As their products grew in complexity, they invested in a 5-axis machine, requiring advanced software capabilities.

New Wave Engineering partnered with us for a seamless transition to NX, enhancing CAD and CAM capabilities and training employees. The integration empowered their engineering and production departments, streamlined workflows, and improved product quality, making them competitive and innovative in various industries.