Case study

Freeform Technology: Integrate Design with Tooling and Optimize the Manufacturing Process

CONTACTBusiness Challenges

- Maintain quality and speed as company grows

- Diversify across a range of sectors

Keys to Success

- Integrated CAD/CAM/CAE capability

- Automatic standard settings and templates

- Flexibility to customize toolpath

Results

- 24 hours from CAD to completed component

- Absolute accuracy

- Up to 50 patterns created per day

Case study Freeform Technology

Fractions of a second, microns of tolerance; in the exacting world of Formula 1® racing, triumph and failure are not far apart. With a background in that demanding environment, the two metalwork engineers who founded Freeform Technology in 2008 know the significance of meeting a specification exactly and delivering on time. Spotting a market opportunity to apply precision machining methods in the composites field, Simon Burchett and Fred Hutton founded the company in 2008 with one machine and some hand-me-down tools.

Now they have five machines, more than 20 employees and provide a range of services: tooling design and manufacture; pattern and model making; prototyping and design mock-up; and full project management of part manufacture.

Business Challenges

From the beginning, they knew that they wanted to use NX™ software from product lifecycle management (PLM) specialist Siemens Digital Industries Software. “We were familiar with NX, we knew it could do the job, and it was one thing we could rely on in the scary days of being a start-up,” comments Burchett. “Just to be sure, we did a bench - mark test on other software, but we found that it was just not as good as NX.” Freeform Technology quickly established a reputation for providing Formula 1 race car standards to the composite tooling industry. “We deliver an extremely accurate product very quickly,” says Burchett. “Our ongoing business challenge is to maintain that quality and speed as we grow across different industries.” Consistent quality, fast fulfilment

The company has four floating licenses of NX CAM (computer-aided manufacturing), enabling the software to be used by various members of the team. Well-established as a partner of Siemens Digital Industries Software in the United Kingdom (UK), Emixa helped Freeform Technology to set up the system and provides ongoing technical support. “The software is excellent, and the guys at Emixa are very knowledgeable,” says Hutton. “They are available when we need assistance and always very helpful.”

Keys to Success

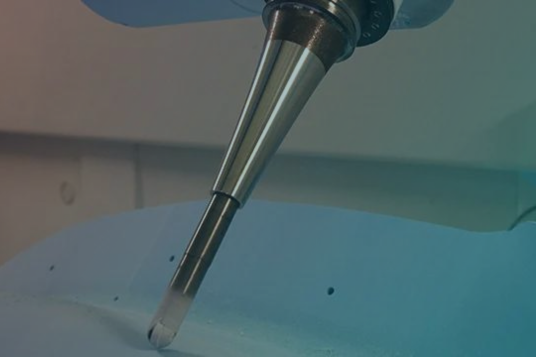

Freeform Technology’ specialists use a customer’s computer-aided design (CAD) models and material specifications for tooling; or, using 3D laser scanning, they reverse engineer a component design in order to develop and manufacture patterns and tooling. The engineers check all CAD files thoroughly so that they are correct and optimized for manufacturing. In some instances, they recommend design changes. With some aspects of CAD included in the NX CAM licenses, Freeform Technology' engineers also have design functionality. Instead of returning files that require amendment, they save precious time by making modifications on behalf of their customers. “It’s a huge benefit to have an integrated design and manufacturing package,” notes Jake Oliviera, general manager at Freeform Technology. “We can be very quick.”

Burchett and Hutton have a deep understanding of tooling processes and procedures and, building on that, they have developed a range of templates within NX CAM. These are preset CAM files with predetermined tool settings and cut depths. Similarly, all machines are set up with identical options for tools, tool builds, speeds and feeds. Providing consistency, these measures also facilitate a smooth process when CAD files are received from a client, usually in Step or IGES format.

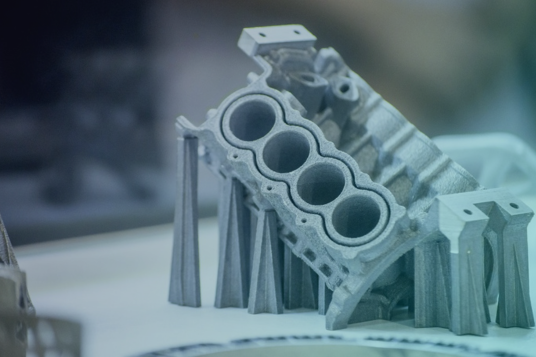

The majority of Freeform Technology' business is the manufacture of patterns for carbon fiber components. The turnaround from CAD model to a finished pattern ready for molding can sometimes be achieved in just 24 hours. All patterns are custom-made by Freeform Technology, which has a team of dedicated offline programmers. What they write one day will be on the machine later that day or the day after. The company completes up to 50 patterns a day at its busiest times. Freeform Technology also has the capability to produce aluminum molds according to customer requirements.

One time-saving feature of NX that is particularly beneficial to Freeform Technology is the capacity to program one side, and then choose to regenerate the model in mirror image. As most cars have matching left- and right-hand side components, this not only saves programming time, it means that partner components can be loaded on two separate machines at the same time.

Results

Freeform Technology' strategy is to continue growing the business in motorsports and respond to demand from new sectors, such as aerospace, defense, energy, leisure, marine, medical, and oil and gas. Although existing clients supply their own data, the two directors are offering additional services, including adding powerful design services using NX CAD.

“Previously, we subcontracted to specialists when clients needed significant CAD input, but it is more efficient to bring it in-house, especially for complex designs. We have more control over the manufacturing process and can focus on reducing our clients’ costs.” For Burchett, the key is to expand without losing focus on quality and delivery, because that has underpinned the company’s success to date.

“NX is fundamental to our operation; the next step is to implement Teamcenter® for complete lifecycle management. Together, they will help us stay on top, as well as see what else we can offer.”