Speak to Our PLM Specialists

Discover how PLM solutions could transform your business.

Seamlessly integrate design, simulation, manufacturing, data and projects for a holistic and efficient product development lifecycle.

Foster collaboration among teams, ensuring instant sharing of data, reducing errors, and accelerating decision-making.

Unleash creativity with advanced design tools, allowing for complex designs, iterations, and simulations to bring innovative ideas to life.

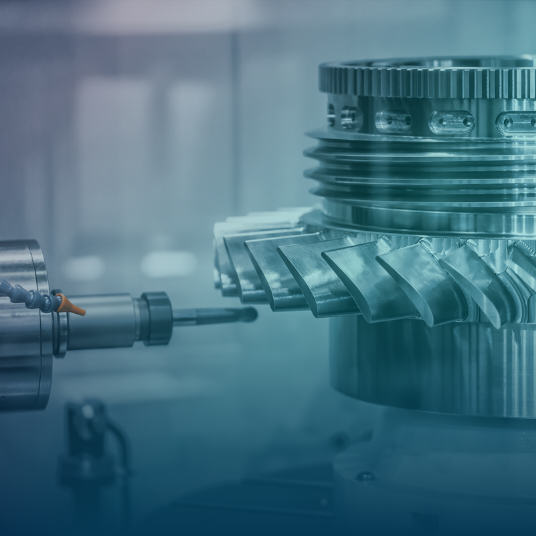

Manufacturing software ensures precision in processes, optimising toolpaths, reducing waste, and enhancing overall production efficiency.

Use simulation tools to predict and refine product performance, reducing the need for physical prototypes and minimising design flaws.

Data & Project Management software provides secure data management, version control & compliance, ensuring regulatory adherence & IP protection.

Discover how PLM solutions could transform your business.

Discover how our Product Lifecycle Management solutions streamline processes, optimise efficiency, and elevate innovation. Explore our comprehensive approach, incorporating advanced technology and expert engineering to revolutionise product development, from conception to retirement. Learn how our dedicated team, proficient in utilising Siemens software, continues to shape the future of Product Lifecycle Management.

Discover the transformational power of our PLM solutions through our compelling partnership with ART Group. Explore this case study to witness how our expertise and innovative technology have propelled ART Group to new heights in product development and lifecycle management, revolutionising their operations and achieving remarkable results.

%2015%25.png)

In the dynamic world of confectionery, Mr. Mallo stands tall as a European marshmallow pioneer since 1907. Seeking expansion while maintaining quality and cost-effectiveness, the company incorporated product lifecycle management to revolutionise their approach to production. Through simulation-driven strategies, Mr. Mallo redefined their manufacturing landscape, optimising operations, and achieving remarkable efficiencies.

Ensure optimisation of your manufacturing processes with our in depth CAM training courses.

That’s what our 530 professionals thrive on every day. How to create business value and increase your competitive advantages?

Emixa is a group of companies with a focus on the manufacturing industry. The ultimate industry where our competences and interests come together.

No one can predict the future, but you still have to prepare for it. We’ll help you to the next stage. Fasten your seatbelts. Get ready for the future.